General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

Optional Rollforming Equipment

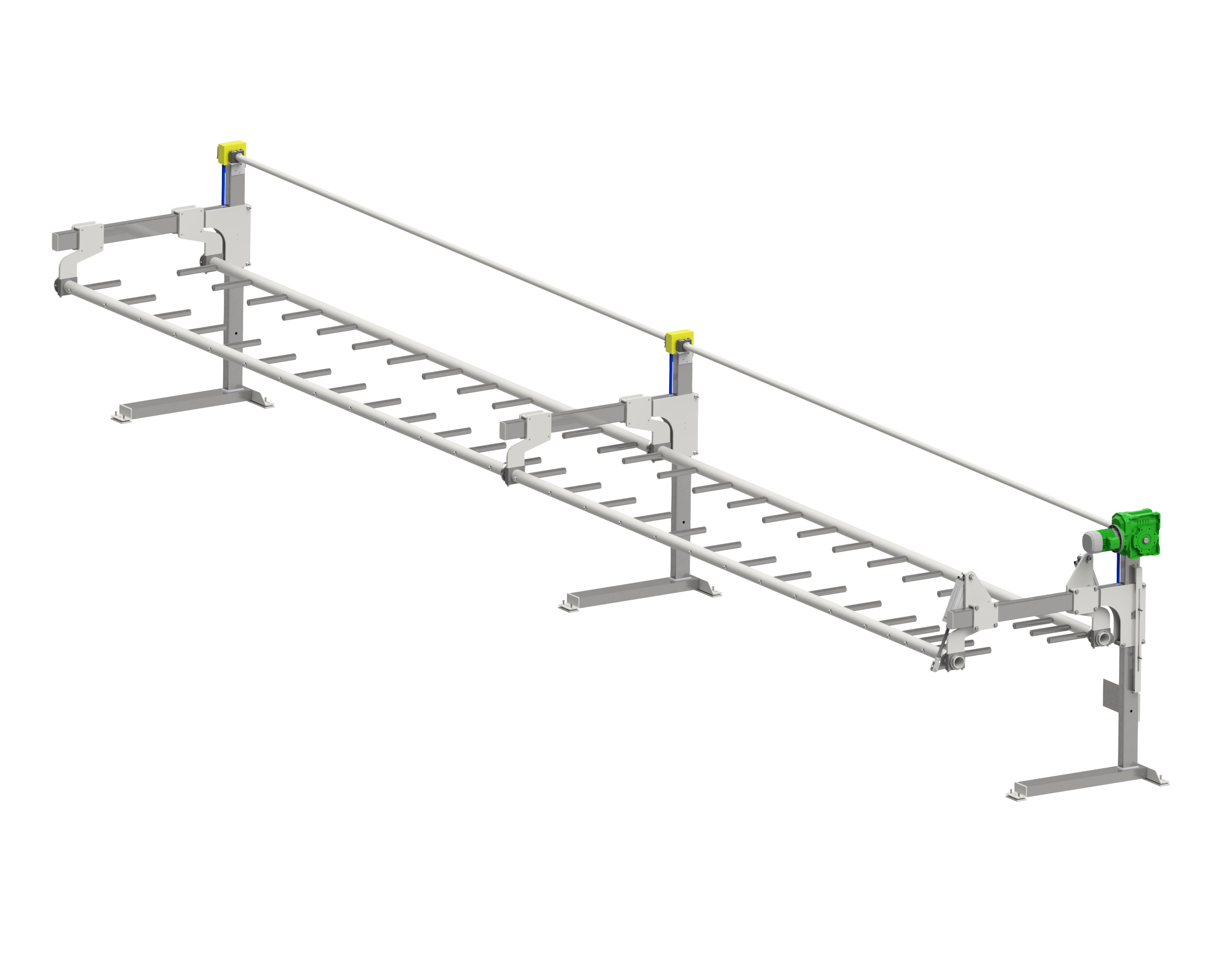

Finished Product Handling

Hayes International offers a range of product handling options, from fixed runout tables for manual offloading to drop tables. These tables stack finished products after each cut, ready for packing.