General Manager Damien Sauni needed a partner to build a fully custom Rollforming machine — one that could manage the high output of a diverse product offering, with minimal operator intervention. After a long relationship of 40 years, Hayes International was, in Damien’s eyes, the best partner for the job.

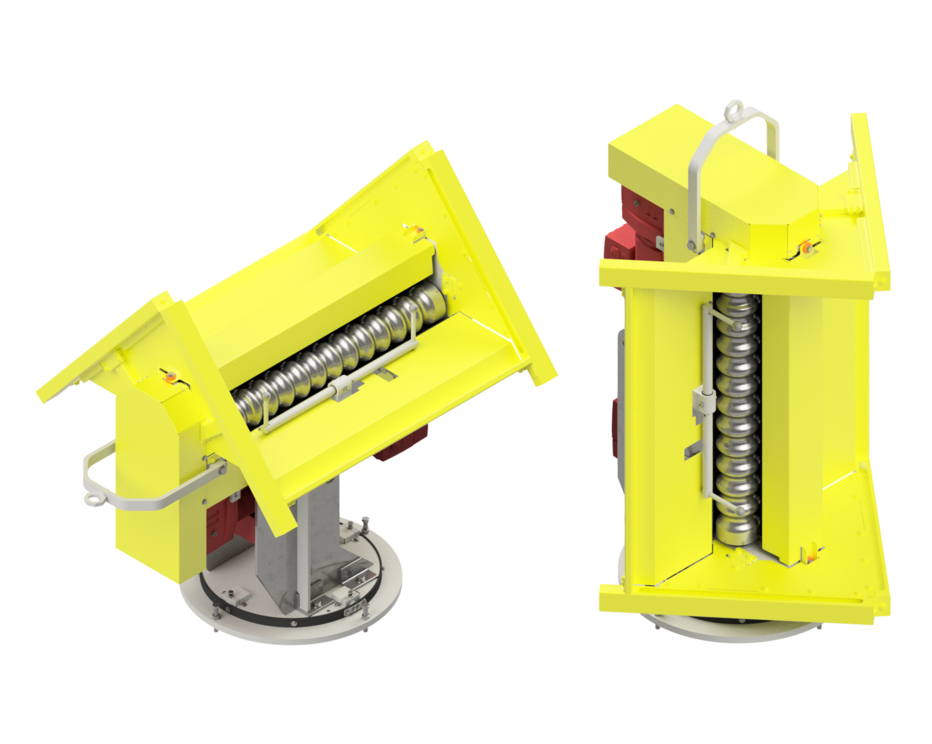

Autocurver

The Hayes Autocurver II is designed to roll-curve standard 76.2mm pitch corrugate sheets for various applications including architectural and liquid storage tanks, supporting most in industry standard coatings including, Galvalume/Zincalume, Pre-painted steel, strippable film, and aqua plate.

Hayes Autocurvers can be operated automatically or manually via a control panel containing a PLC and a PC interface with unique Hayes software that allows complete flexibility of operation including order loading, pre-programmed curves, and software utility for solving dimensional parameters and more.

Read More

Autocurver Standard Components Details

- Welded steel plate design painted with lacquer finish.

- Pivoting base allows for operation in vertical and horizontal configurations.

- CNC precision machined from k1045 solid steel rolls.

- Coated with a hard chrome finish for durability.

- Tooling rolls driven via VFD electric gear motors.

- Main tooling is driven by a 1.5Kw Electric gear motor coupled via chain and sprocket drive.

- The secondary drive system is powered by a 2.2Kw Electric gearmotor.

- Main drive and pinch point guards are included with the standard Autocurver II.

- Light curtain guards can also be positioned on the infeed and outfeed sides of the machine. The guards are programmed to ignore the profile being curved, but as soon as any foreign object passes through the light guards, the Autocurver stops and needs to be restarted at the operator console.

- The Hayes Autocurver is controlled via a panel-mounted PC and PLC from a standalone control panel that can be operated manually or automatically.

- Utilizes Hayes software specifically for Autocurvers. The software allows the operator to make multiple passes for bull nosing, circular tanks, barrel vaults, and others, as well as automatic tank modes for quad and slimline storage tanks.

- Stroke reduction to minimize tangent point marking on the material, automatic repositioning between curves in tank mode, automatic sheet pre-positioning and sheet pitching, program storage and recall, and a software utility for solving dimensional parameters.

Request A Quote

If you’re ready to take the next step, let us know below. One of our team can get in touch to talk through your project. If you’d like to share a drawing, attach it below. We look forward to receiving your enquiry.