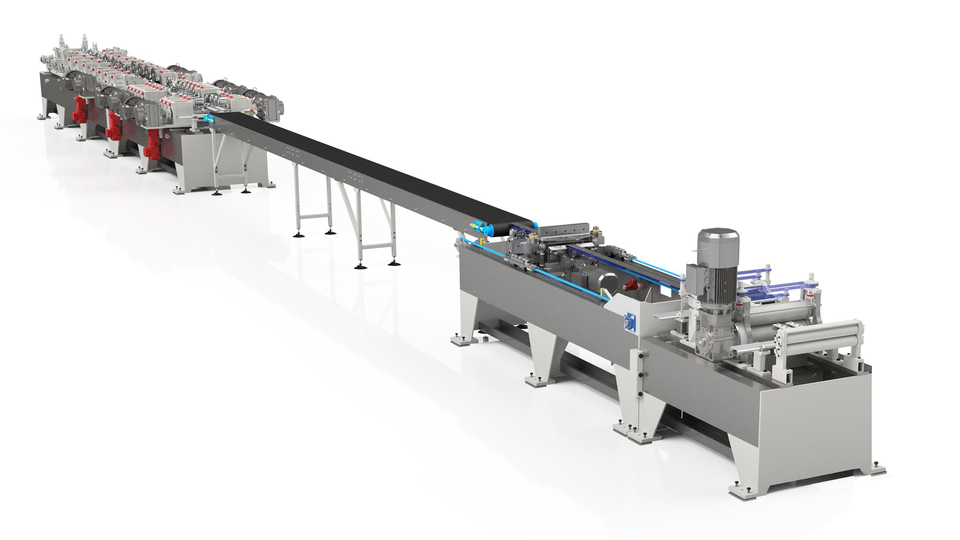

The Hayes RC Stud Mill is a versatile, affordable and simple to use solution for metal framing production. With infinitely variable sizing within machine specifications and capable of manufacturing a wide range of framing profiles from Plain channels and Cee sections through to box sections and odd leg channels. Complete with Hayes 'Rapid change' system and Hayes 'Auto-gauge' system changing profile specifications and coils is fast and requires minimal operator skill or input.

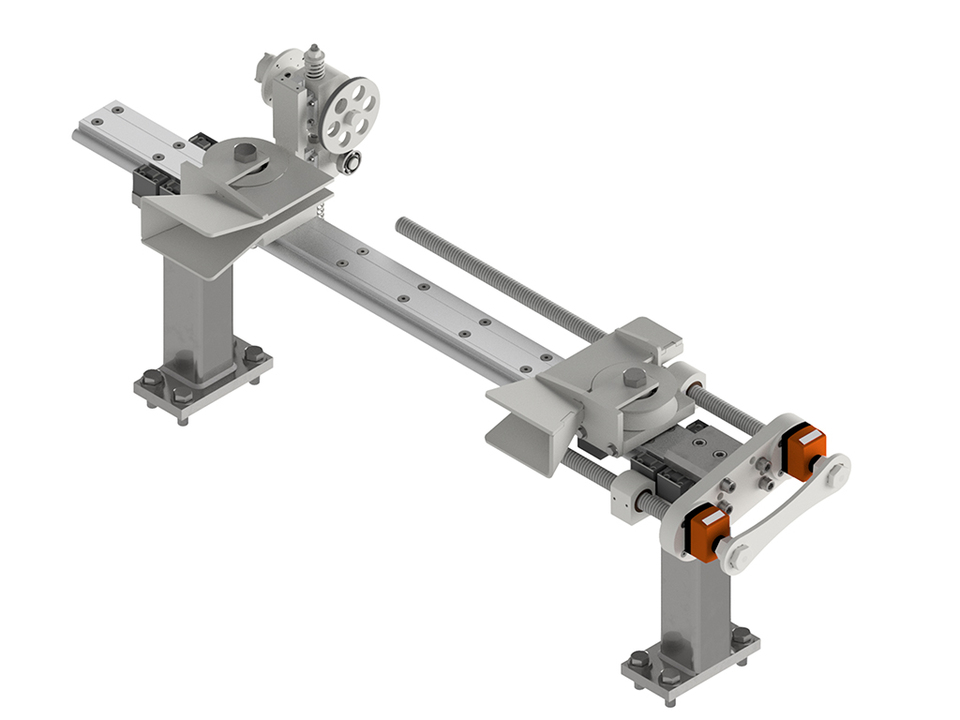

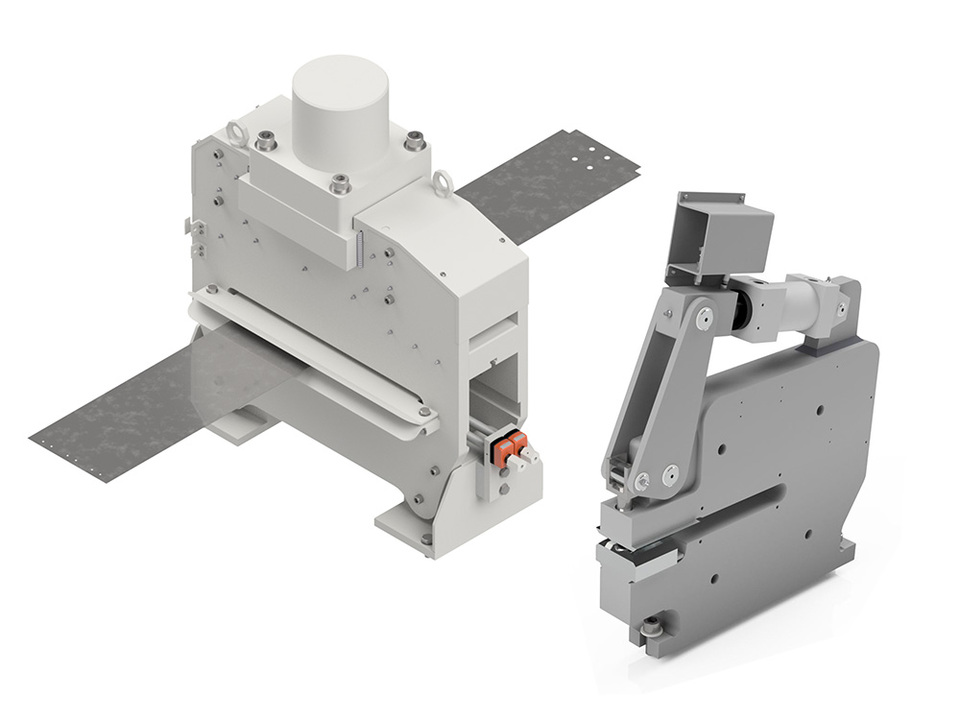

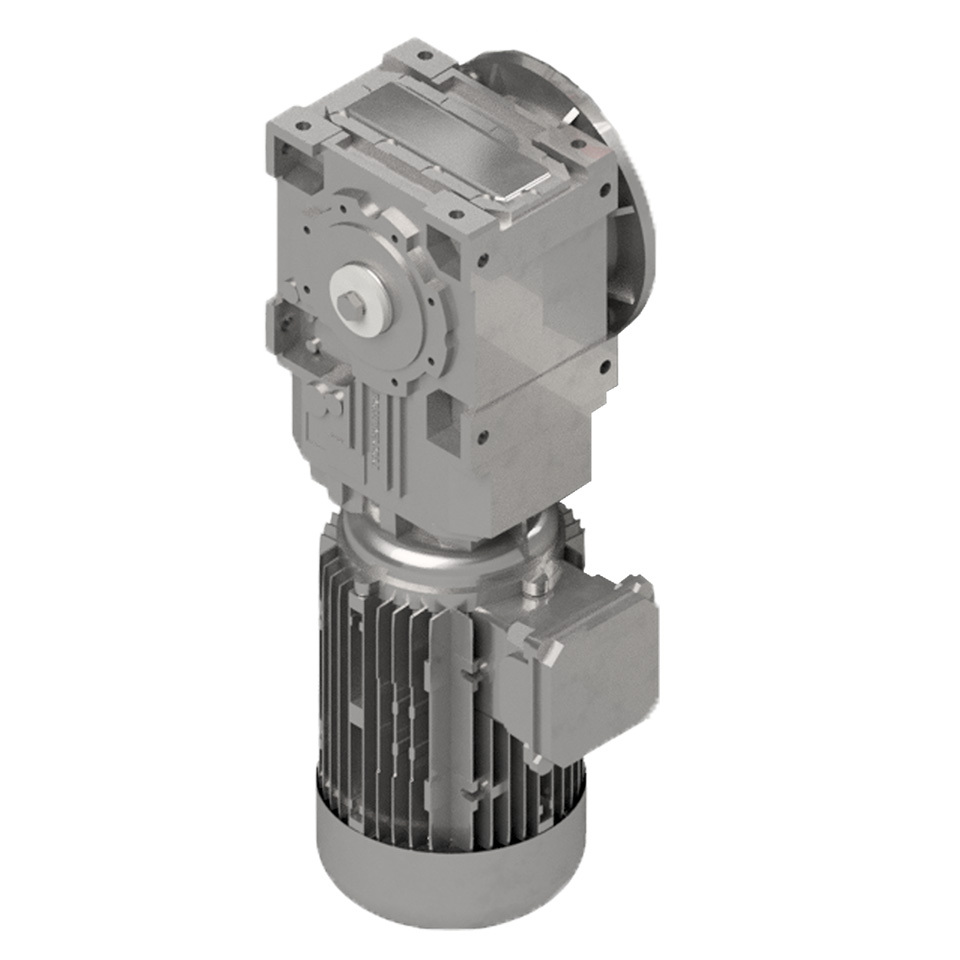

RC STUD MILL STANDARD COMPONENTS

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.