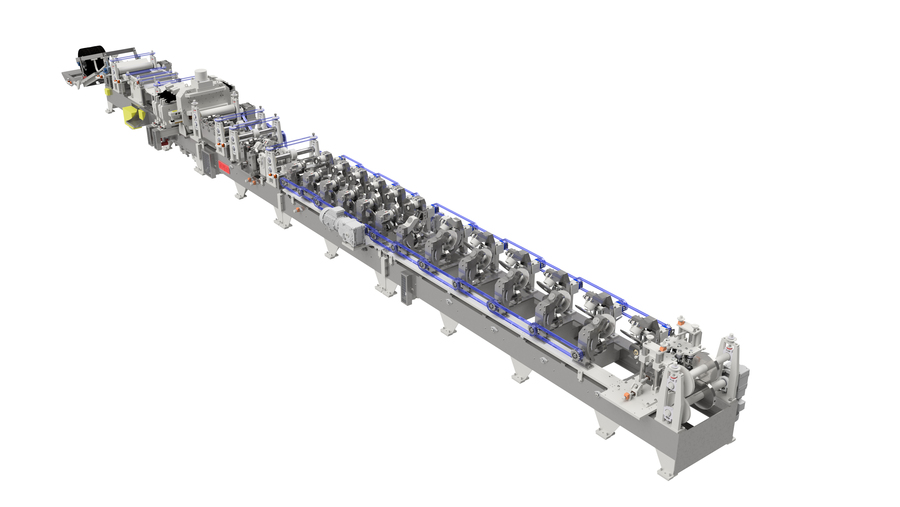

FC 'Fast Change' Purlin Mill

The

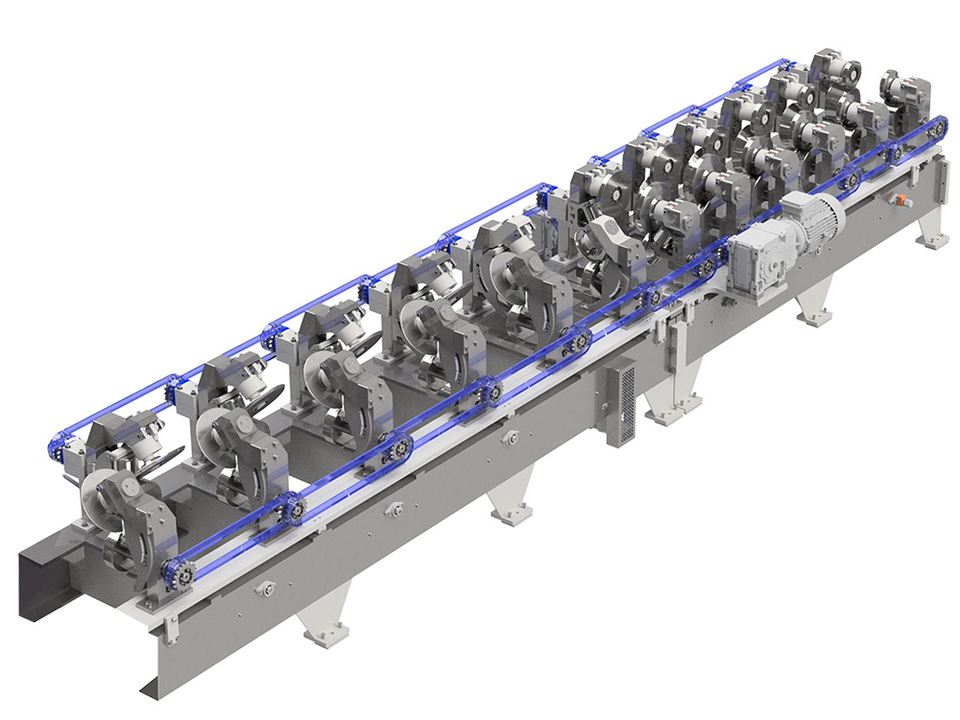

Hayes FC Purlin line is a development on our QC purlin line. Bringing the same

proven and tested design from our QC purlin lines, the FC Purlin introduces our

‘Fast Change’ system to make changing from Cee to Zed purlins and purlin sizes

faster and easier, while still letting you produce any size purlin within

machine specs.

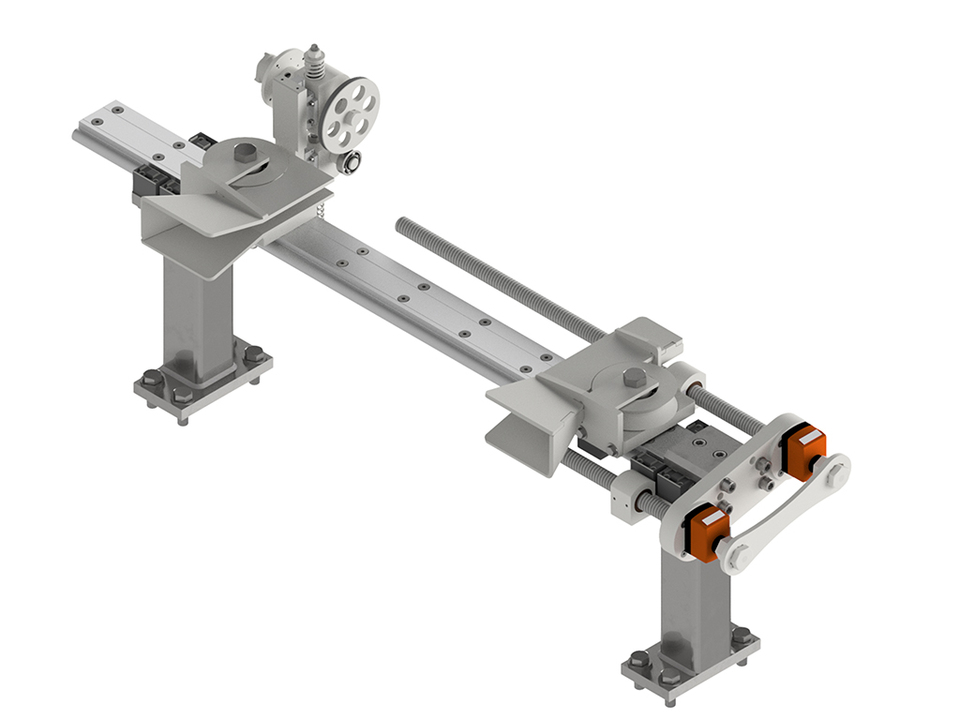

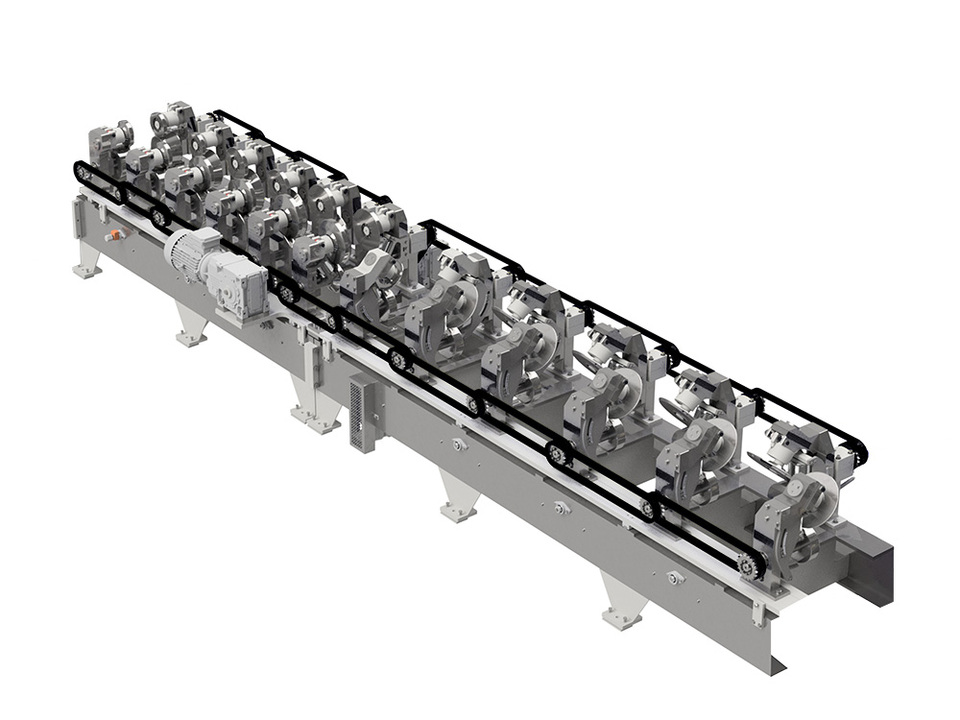

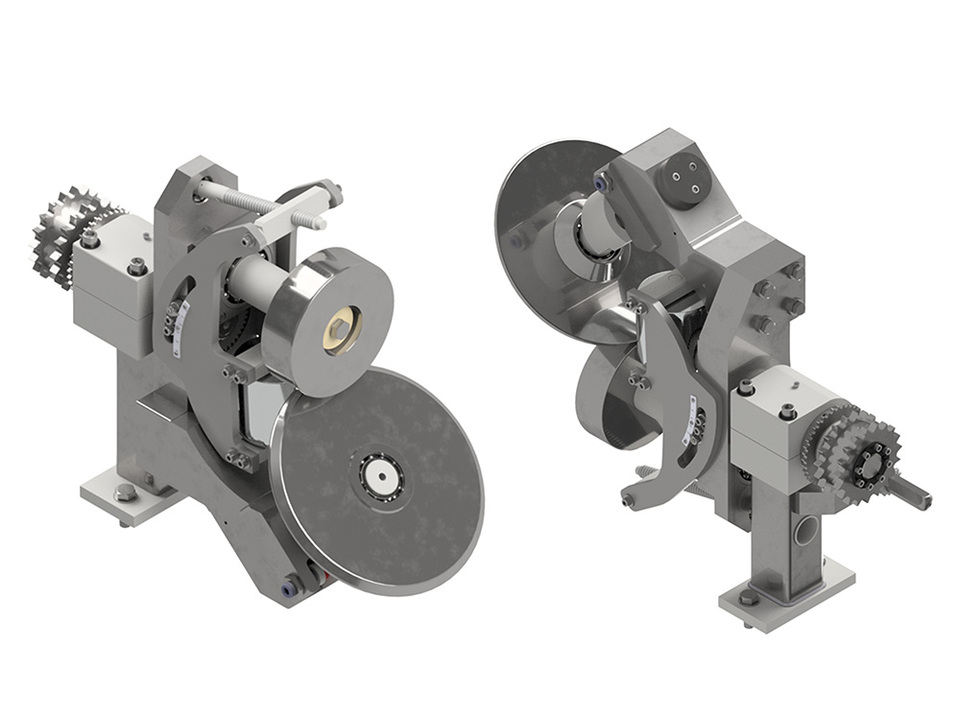

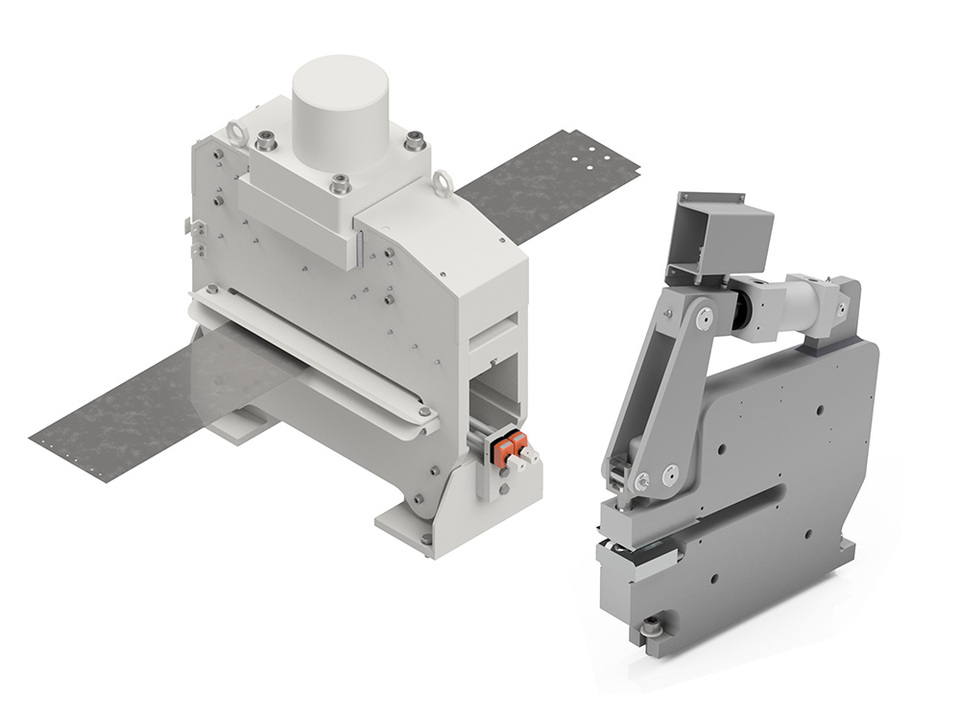

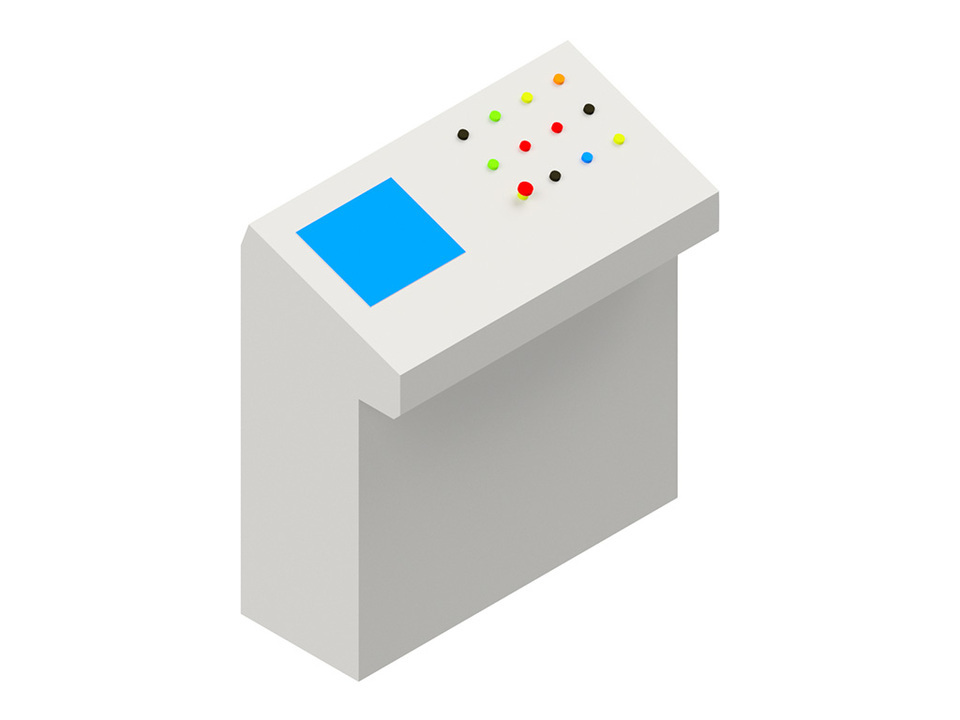

'FAST CHANGE' PURLIN STANDARD COMPONENTS

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.