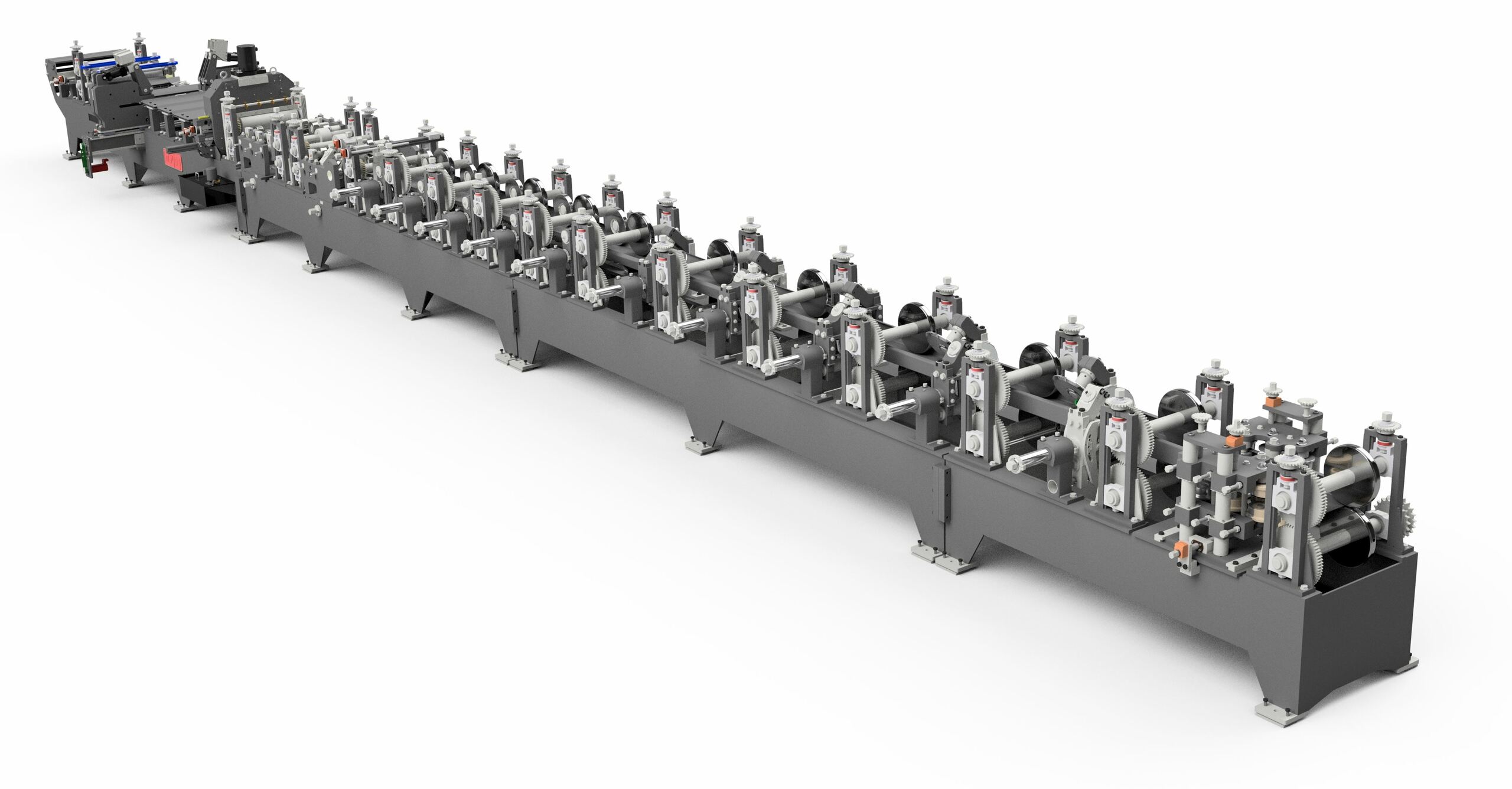

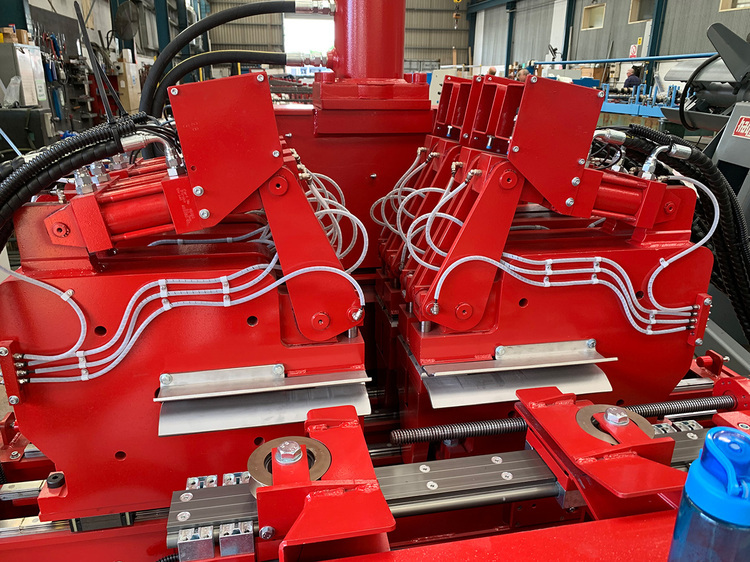

QC 'Quick Change' Purlin Mill

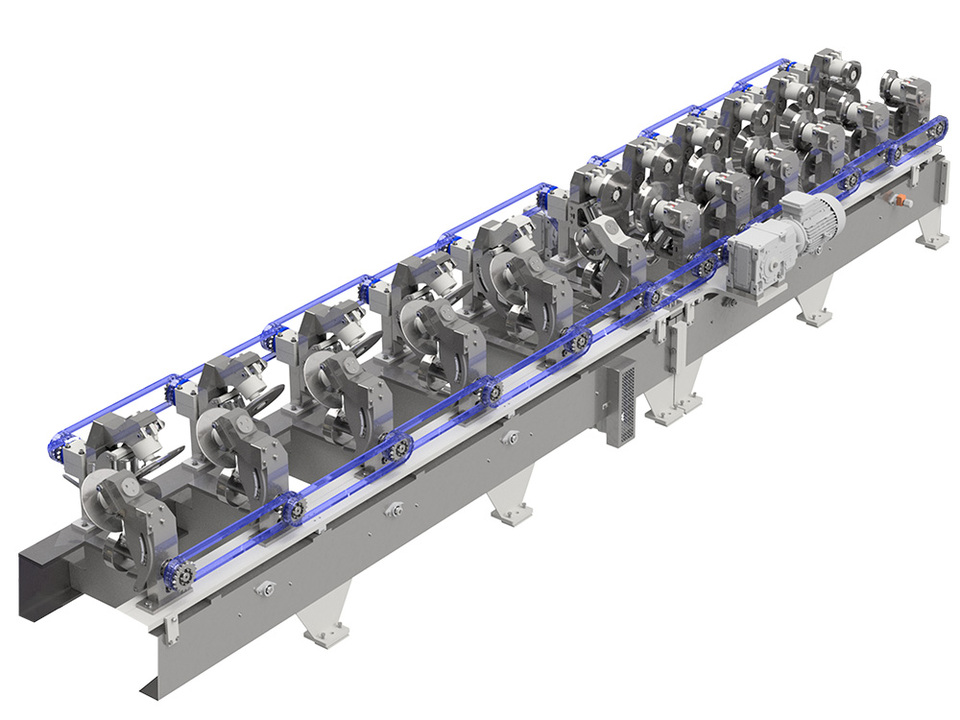

The

Hayes QC Purlin line has been developed and proven in the field to be an

efficient and cost-effective solution for the medium volume producer. It has

many features that would be found only on more expensive and larger lines, the

Hayes QC Purlin incorporated the patented Hayes ‘Quick change’ system which

allows any size purlin to be produced within the specifications of the machine

quickly and easily.

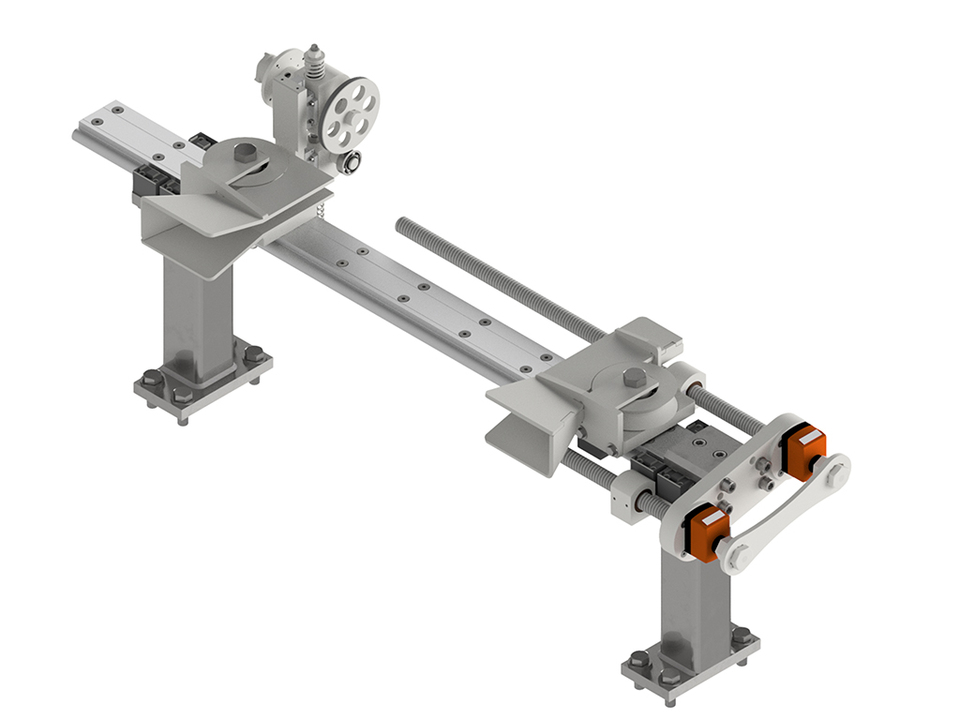

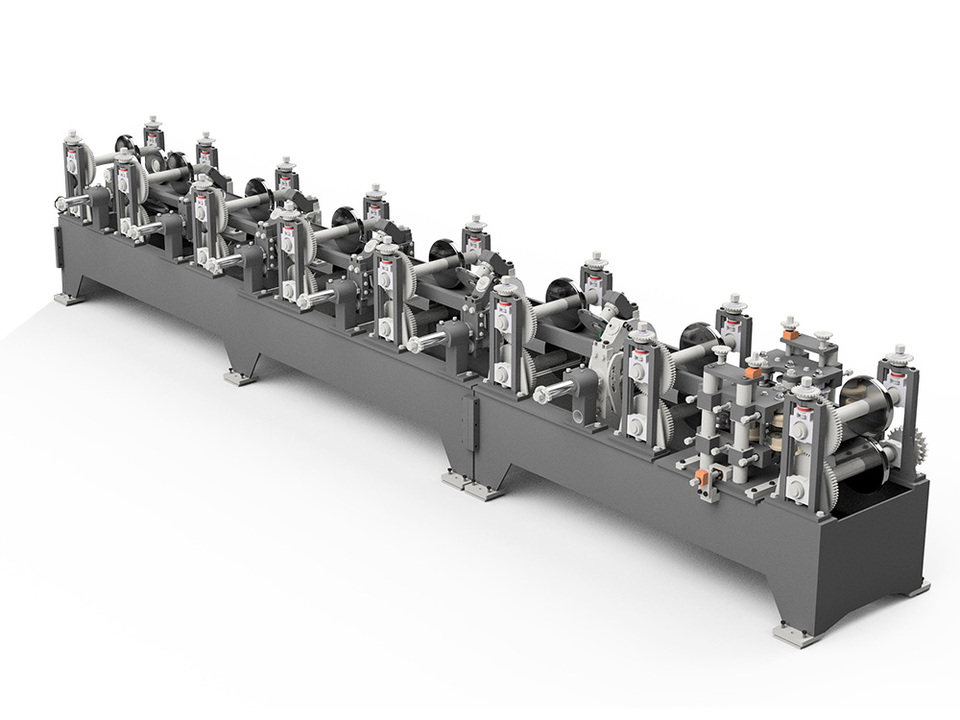

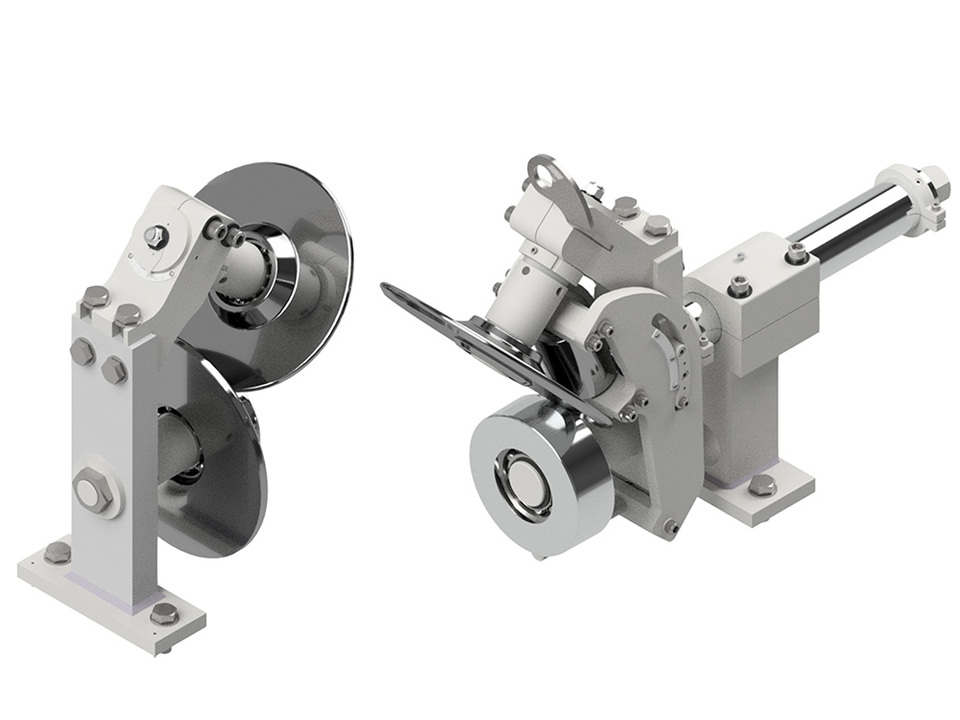

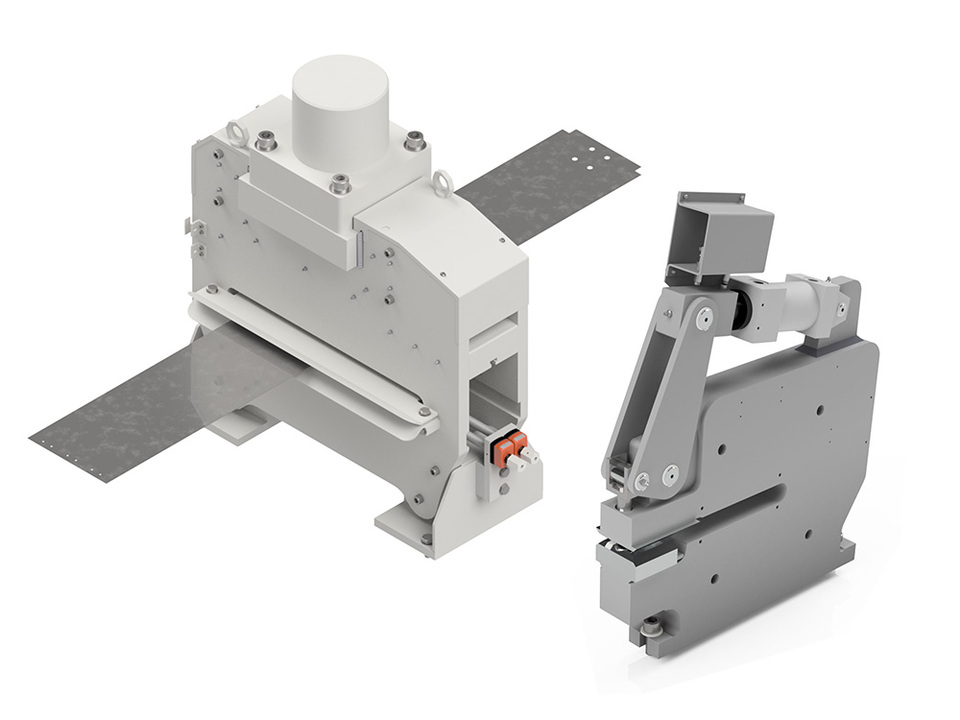

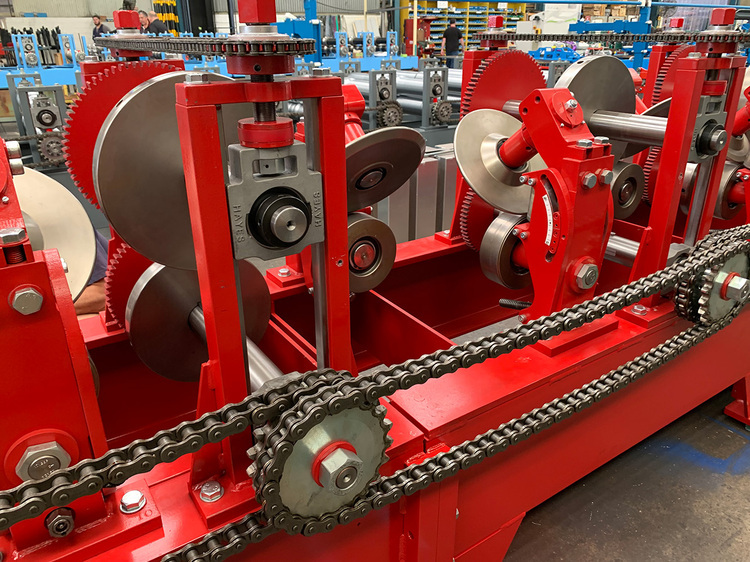

'QUICK CHANGE' PURLIN STANDARD COMPONENTS

GALLERY

CONTACT OUR SALES TEAM

For any queries or to request a quote please contact our sales team.